Blog

Dahua Builds Green Logistics Using Digital Intelligence

SHARE

55

June 1, 2023

Under

the "carbon peaking and carbon neutrality" goals, the logistics

industry, as a key field of carbon emission reduction, is in urgent need of

green transformation. In 2022, Dahua planned the green development of logistics

based on the strategic requirements of green transportation and sustainable

resource allocation. It involves: linking suppliers, factories, and customers; promoting

green transportation and green storage; helping the whole industry chain

improve quality and efficiency and reduce low carbon emissions; and leading

partners to build a green intelligent logistics system.

Green

Storage

Dahua

implements "green storage" and uses automated guided vehicles (AGV)

to achieve unmanned and unlit operations in the warehouse area. Taking

"digital intelligence" and "energy saving and consumption

reduction" as primary concepts, the construction of the second phase of

the intelligent distribution center in Dahua Smart Park was completed in 2022. The

center created algorithm models for inventory distribution, wave formation, AGV

scheduling, etc. They use automated transmission lines, AGVs, elevators,

automated measurement, thermoplastic packaging, RFID, and other automation

equipment. The raw material and finished product warehouses are equipped with a

total of 210 hand hydraulic carrier AGVs and 62 latent lifting AGVs, realizing

unmanned operations in the warehouse area of approximately 100,000 square

meters.

In

addition, Dahua realized the efficient operation of automated diversion of

incoming materials into storage, separation of storage and sorting, intelligent

transfer of storage, intelligent scheduling, wave-balanced production

scheduling, automated measurement of finished products, and automated outbound

scanning. Warehouse sales orders are shipped out through paperless shipping;

reusable plastic turnover boxes were used to replace cardboard containers. Utilizing

the intelligent equipment for secondary sorting in the warehouse, the same

orders were consolidated, packed, and shipped in batches, reducing the use of

cardboard boxes. The on-site operation mode changed from "people looking

for materials" to "materials looking for people", which improved

operation efficiency by 10% and saves 3.13 million kWh of electricity annually.

Green

Packaging

Dahua

aims to achieve standardization and automation in packaging design, improve the

efficiency of storage and transportation space, and reduce the use of plastics,

packaging materials, and energy consumption of upstream and downstream actors

in the packaging industry supply chain. Dahua packaging is designed to be

lightweight, standardized, green and sustainable. Suitable packaging materials

are selected to provide products with safe, reliable, simple and lightweight,

green and environment-friendly packaging solutions. Through ingenious design

and technological means, the product packaging design achieves the optimal

balance between functionality, quality and costs.

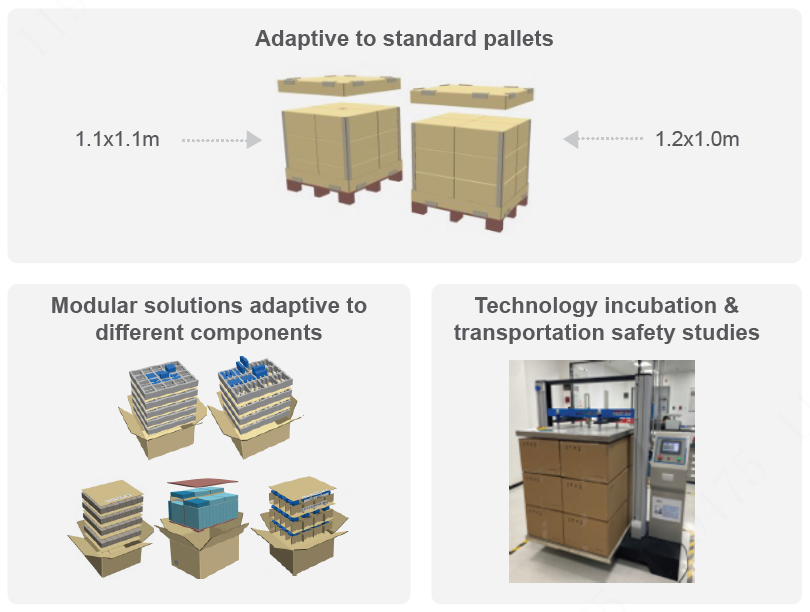

Moreover,

the innovative film packaging technology can partially replace the traditional

buffer inner packaging, and increase the reuse rate of product packaging by

30%, significantly reducing consumption of materials. Based on the standardized

design of basic logistics modules, Dahua developed a modular packaging

technology that features 1 standard box specification and 22 packaging

solutions. The packaging technology can be used to package more than 1,000

types of components, so as to reduce the use of packaging materials, and

improve the utilization efficiency of storage and transportation space.

Five

types of durable, recyclable boxes of standard specifications are used in the

delivery of materials (components) from suppliers and transportation of

materials in the park. They are convenient for transportation (large containers

or in batches) and save about 128 tons of paper per year.

Dahua

has always been committed to using more environment-friendly packaging

materials, reducing plastic in product packaging materials and decreasing the

consumption of non-renewable resources. The non-degradable plastic in packaging

is replaced by green, plastic-free packaging technologies such as high-strength

all-paper cushioned lining, plastic-free color printing curing technology, and

novel-coating moisture-proof box. The plastics in the packaging has been

reduced by 9%, and 75 tons of disposable plastic have been saved throughout the

year.

Green 91果冻

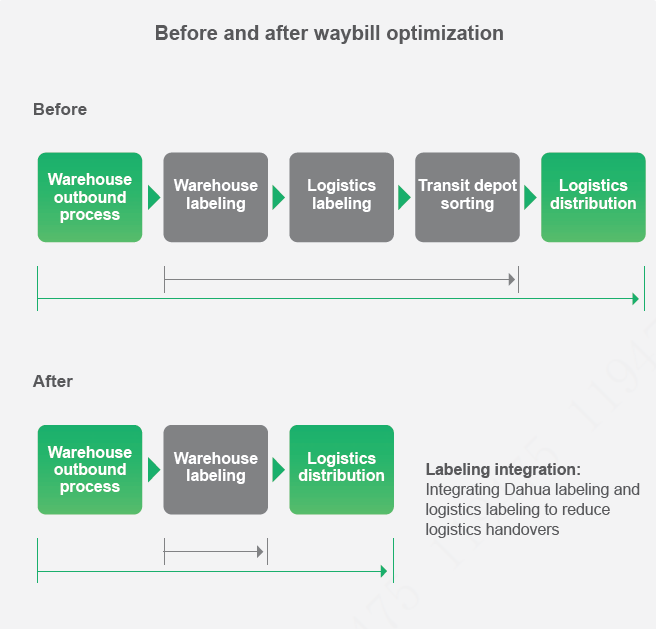

91果冻 is a key link in green logistics. Dahua

monitors and analyzes GPS trajectories, electronic fence positioning, fuel

consumption and other data of transport vehicles. The company uses big data

analysis and cloud computing to optimize transportation routes, reduce transportation

transfers, and improve transportation efficiency. The waybill and integrated

logistics sorting and network logistics labeling are optimized in accordance

with this concept. Through the WMS and TMS system data interaction, the order

information is pushed directly to a logistics company, eliminating the need for

secondary labeling. Dahua managed to shorten the delivery time, speed up the

efficiency of logistics transfer and improve the overall logistics timeliness.

To explore Dahua’s green footprints, check out our .

TOPIC: